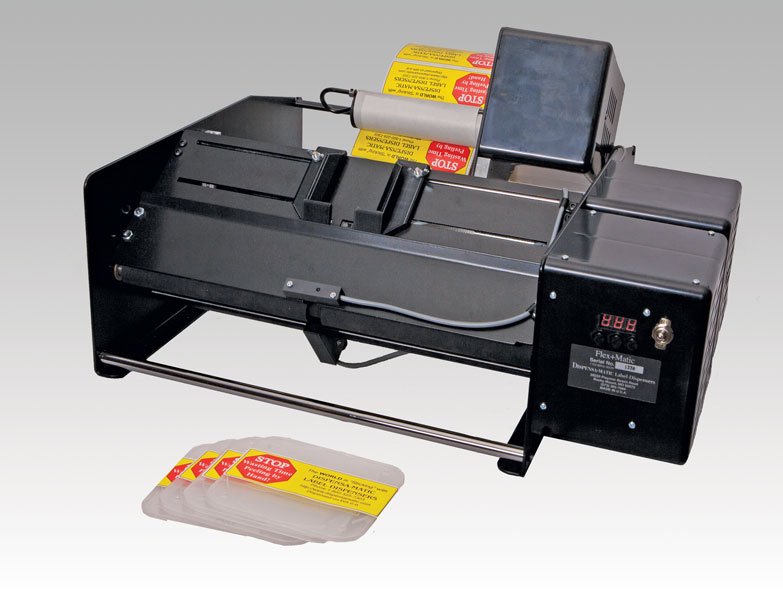

Motorized Channel Slide Wipe

A unique semi automatic wipe-on type label applicator. This tabletop unit applies labels to flat surfaces and is especially useful for applying long labels that wrap around sides of containers.

LabelOn™ Tamp Label Applicators are designed with compact robustness in mind. They are powerhouses in small packages that allow for production on a smaller scale without compromising the quality of labelling. LabelOn™ ‘s lineup consists of highly accurate and proficient semi-automatic labelling machines which are undoubtedly a step up from hand labelling.

Semi-automatic Labelling Machine for Bottles

A semi-automatic tamp type label applicator. This tabletop unit applies labels to flat and slightly curved surfaces.

Small Labeling Machine Features:

- Electric motor advances labels. Motor is footswitch activated and light sensor controlled. Labels are held on the machine for the operator to apply by wiping onto an article.

- Can label flat articles of any size.

- Ideal for labeling cartons, square bottles, CD/DVD cases and clamshell containers.

- Can apply labels that wrap around corners. Very useful for cartons, bakery boxes, plastic deli containers.

- Liner paper is rewound for easy disposal.

- Optional digital counter available.

Mini Labeling Machine Specifications:

- Label supply roll – max 10” diameter, 3” core ID

- Label length :

• 5 1/8” to 7 1/2” with 4” channels

• 7 1/8” to 9 1/2” with 6” channels

• 9 1/8” to 11 1/2” with 8” channel - Label width: 1 1/2″ min, 5 3/4″ max

- Die cut labels with a minimum 1/8” gap between labels

- Durable steel and aluminum construction. Powder coated finish.

- Electric: 120V AC (240V optional)

- Approx. Weight: 36 pounds

Labeling Equipment Function:

- For labeling flat products

Abilities and Limitations

- Can apply square, rectangular, oval and round labels.

- Contact us if your labels have unusual cutout shapes or are made from very thin (under 3.5 mil) plastic film (BOPP). We recommend sending us samples for testing if in doubt about a label.