Introducing our LabelOn™ Flat Bags Sheets Case Labeling

LabelOn™ helping you take the step from hand applying to machine applied labels. This Flat Label Applicator Machine – Made in the US solves the problem of labeling Flat Bags, Flat Sheets, Flat Case with a benchtop labeling machine.

A good first step is to move to a Benchtop labeling machine.

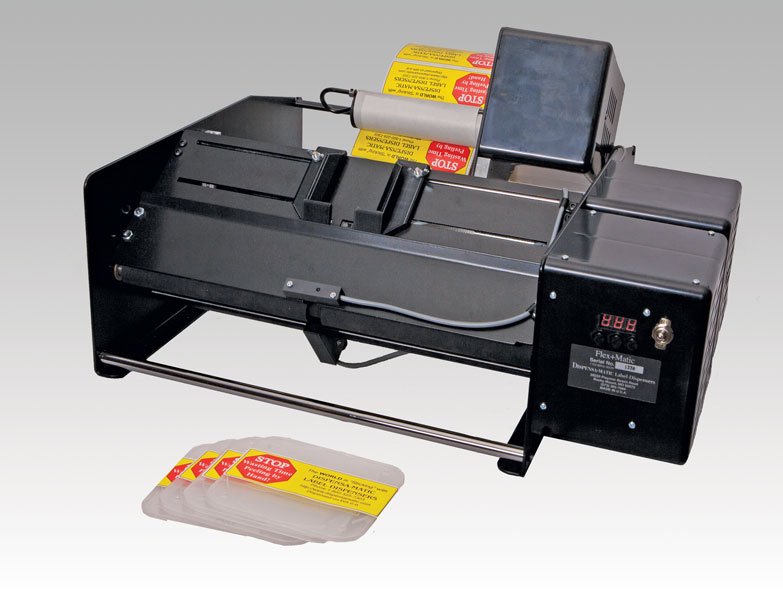

Model: Flat Pack Flat Bag Flex-Matic

Suit Product Width: 50 mm (2 “) to 298mm (11¾ ″) Wide

Suit Product Thickness: Up to 6.5 mm (¼ “)

Labeling accuracy: +/- 1.5 mm (¹⁄₁₆ ″)

Typical Labeling speed: 10 to 20 Pieces / min

Label Length: 25.4 mm (1″) to 380mm (15″)

Label Web Width: 38 mm (1.5 ″) to 203 mm (8.0″)

Minimum Label Width: 25 mm (1″)

Minimum Label Gap: 3.0mm (⅛ ″)

Minimum label thickness: 25.4 µm (1 mil) (subject to testing)

Machine Dimensions: (L × W × H) 12″ × 20.0″ × 24″

Power supply: 115V AC

Label Roll Core: ID 76 mm (3″)

Label Roll Diameter: Maximum OD Φ228mm (9″)