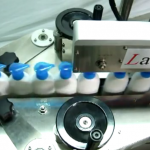

Modular Round Product Labeling

Orientation and Full Wrap Module

The LabelOn™ Modular Label Applicator may be equipped with a Wrap Conveyor Module or an Orientation Module to label an assortment of cylindrical or marginally tapered round bottles. The very simple additions of these modules will accommodate further variety of configurations. The machine allow for the simple plug in of mechanics, electronics and sensors. Other modules can also be incorporated to allow the labeling of one or two sides of an oval or flat bottle. This changeover from round to oval to flat is fast and simple. When flexibility and simplicity of operation are your primary concerns, seek out LabelOn™ Modular Round Product Labeling System. With Wrap Module Production speed of up to 7200 pieces an hour and Orientation Module Production speed of up to 1800 pieces an hour, our machine can take away the bottle neck in your facility and allow for fast completion of medium and large orders.Read More

Modular Flat Sided Product Labeling

Angle Position Labeling Head

A LabelOn™ Modular Label Applicator set up for flat sided product labeling requirements can be counted to have superb accuracy and straightforward settings. Flat sided products requiring on up to three labels is painless to set up again and again where all electronic settings/parameters of your production job can be saved on the touch screen allowing exact repeatability between runs. Variation in bottle shapes and heights have been given particular consideration. Having an option to add more modules, your labeling machine has the ability to change from flat to oval to round product label application job very quickly and easily.

Modular Oval Sided Product Labeling

Angle Position Labeling Head

LabelOn™ has the forethought of design to make the job simple to set-up yet again when you have oval sided products needing one up to three labels. A modular machine labeling a product can be relied upon to have exceptional precision.

To align oval bottles for a steady movement past the labeling heads they need more than guide rails. An oval bottle is free to rotate with only one point of contact on the radius of each side that can lead to substantial label placement variations with probable creasing during wipe down. To deliver significant amount of alignment, we need the Aligning Chains module. This commonly employed strategy provide significant amount of alignment for a range of oval products without having to change parts. A number of options are available to align such oval cross section bottles and these can include: dual scrolls, reciprocating clamps, aligning chains, aligning wheels and conveyor pucks..

Modular Top and Bottom Product Labeling

Top Bottom Magazine Feeder

Frequent application of the LabelOn™ Modular Top and Bottom configuration is the labeling of products from above and labeling from below simultaneously. This is excellent for labeling tubs and jars, lay flat goods like chipboard, books, DVDs or boxes. It is very convenient for adding product identification, nutritional values, warnings or allergen labels. It can be a label only from top or bottom, though in some cases, self adhesive labels are applied from both. The pressure sensitive labels can be nearly the diameter of the product or they can be very small as is the case for over labeling of imported products.